engineered & delivered

facilities

customer delight

Our Products

Body-in-White, abbreviated as BIW, is the bare body of the automobile, consisting of various sections such as under-body, upper-body & closures.

The chassis is the backbone of the vehicle, which supports the entire weight of the vehicle along with passengers. It plays a major role in vehicle ride, handling & .

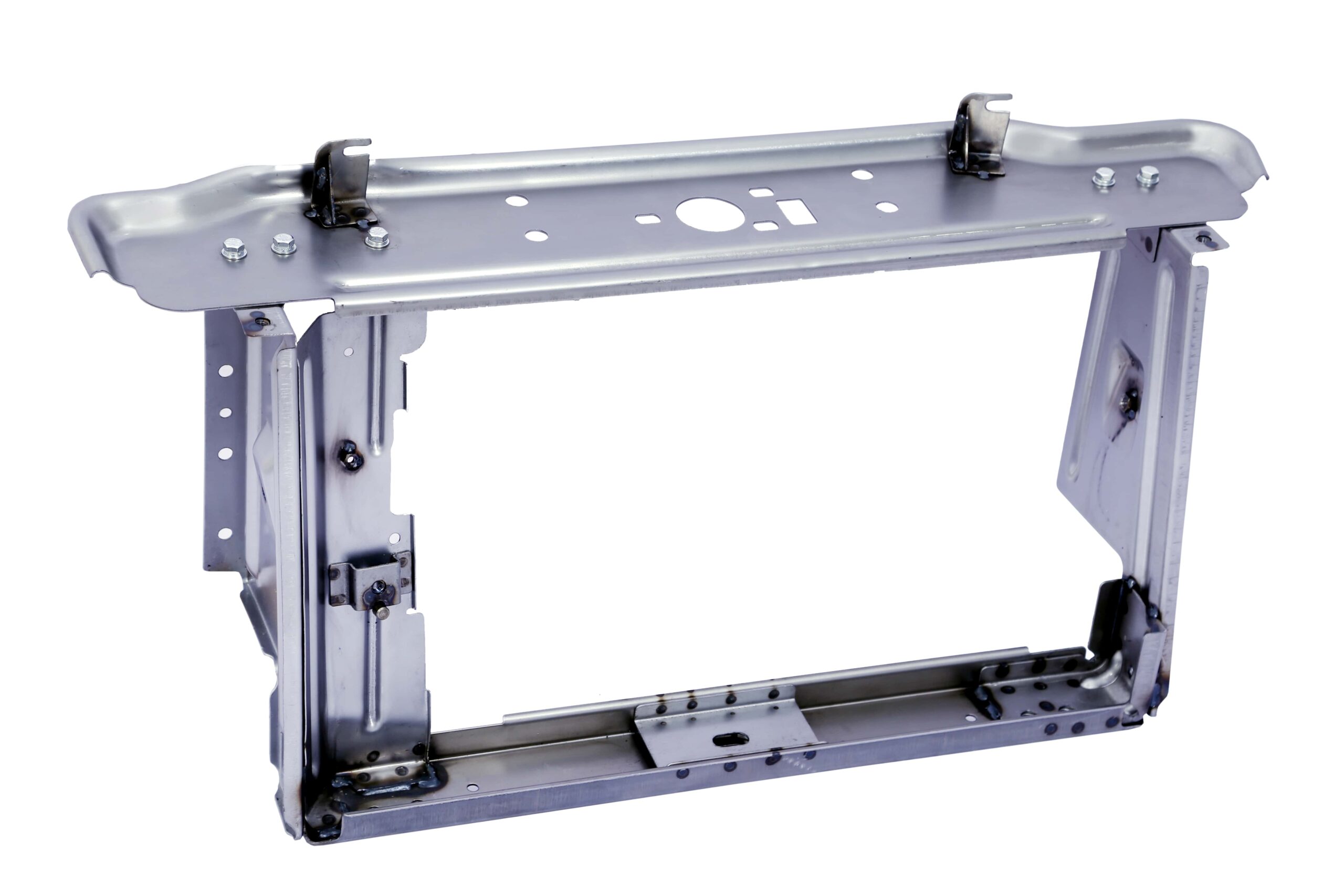

The seat is another vital subsystem of a vehicle, often defining consumer perception of the vehicle as a whole based on comfort and features available.

The cargo body or load body is the big storage compartment at the back of commercial vehicles, which is used to store & transport heavy loads.

ACPPL has been making parts for the agricultural equipment sector for the past 20 years, focusing on A-class parts & assemblies such as tractor.

Why ACPPL

Leading Automotive Manufacturer

Towards Manufacturing Excellence

ACPPL stands out as a preferred supplier partner for several key reasons. We prioritize the fundamental factors that clients seek in a supplier: quality, cost, delivery, experience, reliability, and a customer-first approach. Our internal quality systems ensure flawless product launches and zero defects throughout serial production.

With customer and product-specific teams, we bring a wealth of knowledge and experience to successfully execute projects. ACPPL has built a reputation as a reliable partner in the industry through years of focused customer service.

We consistently prioritize customer satisfaction by always putting their needs first and fostering a culture of teamwork and quick decision-making. Choose ACPPL as your supplier partner and experience our commitment to excellence firsthand.

Driving Success in Four Key Areas

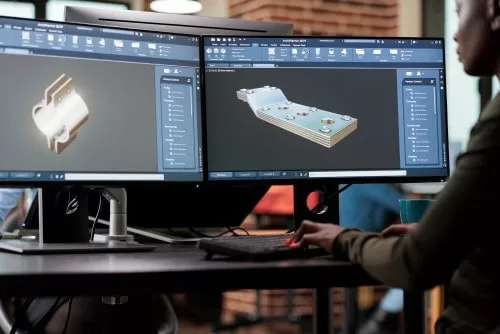

Our comprehensive services cover the entire spectrum of concept generation to mass production. Whether it’s full-service supply (FSS) projects or standalone engineering projects, we have the expertise to deliver outstanding results.

With our in-house toolroom, we have the advantage of offering reduced lead times and exceptional quality for our parts. Our dedicated team ensures efficient tool engineering processes for optimal outcomes.

Our competitive edge lies in our robust manufacturing capability, which is supported by experienced teams and state-of-the-art facilities, ensuring the highest standards of quality and efficiency.

Proudly “Made in India for the world,” we manufacture a diverse range of products that find application in vehicles worldwide, underscoring our commitment to delivering reliable components across the globe.

CLIENTS

Partnering with Industry Leaders